Circular Logistics

Multi-brand-reusable-crate system

How can we simplify and systemize individual beer crates for many different brands in such a way that the logistical advantages of harmonization maintain the appeal of the respective brands? The brewery group Carlsberg’s basic crate system is a sustainable answer.

In 2006, we were asked to design a new, unique beer crate for a premium Carlsberg brand. Given the colourful stacks of dozens of different brand crates in the huge logistics halls, we asked ourselves the question of whether it actually made sense for each brand to have its individual crate.

How much individualization do we need?

Our talks with the marketing and logistics department revealed the significant effort involved in handling individual crates. Also, at some point, the crates no longer corresponded to the latest brand design. Some looked like they had fallen out of time. Our question: Wouldn’t it be much more sustainable if all company brands got the same ‘box’ and their logos were assigned to the same place?

Logistics and marketing: creating a new standard together

It quickly became clear that the idea of a customizable but standard-shaped crate would be a great asset. It was now crucial that the newly designed basic crate could be relabeled as efficiently as possible for all brands. With two effects: Logistics could respond much more flexibly to sales inquiries. And marketing could place the latest branding of the respective brand without any special effort.

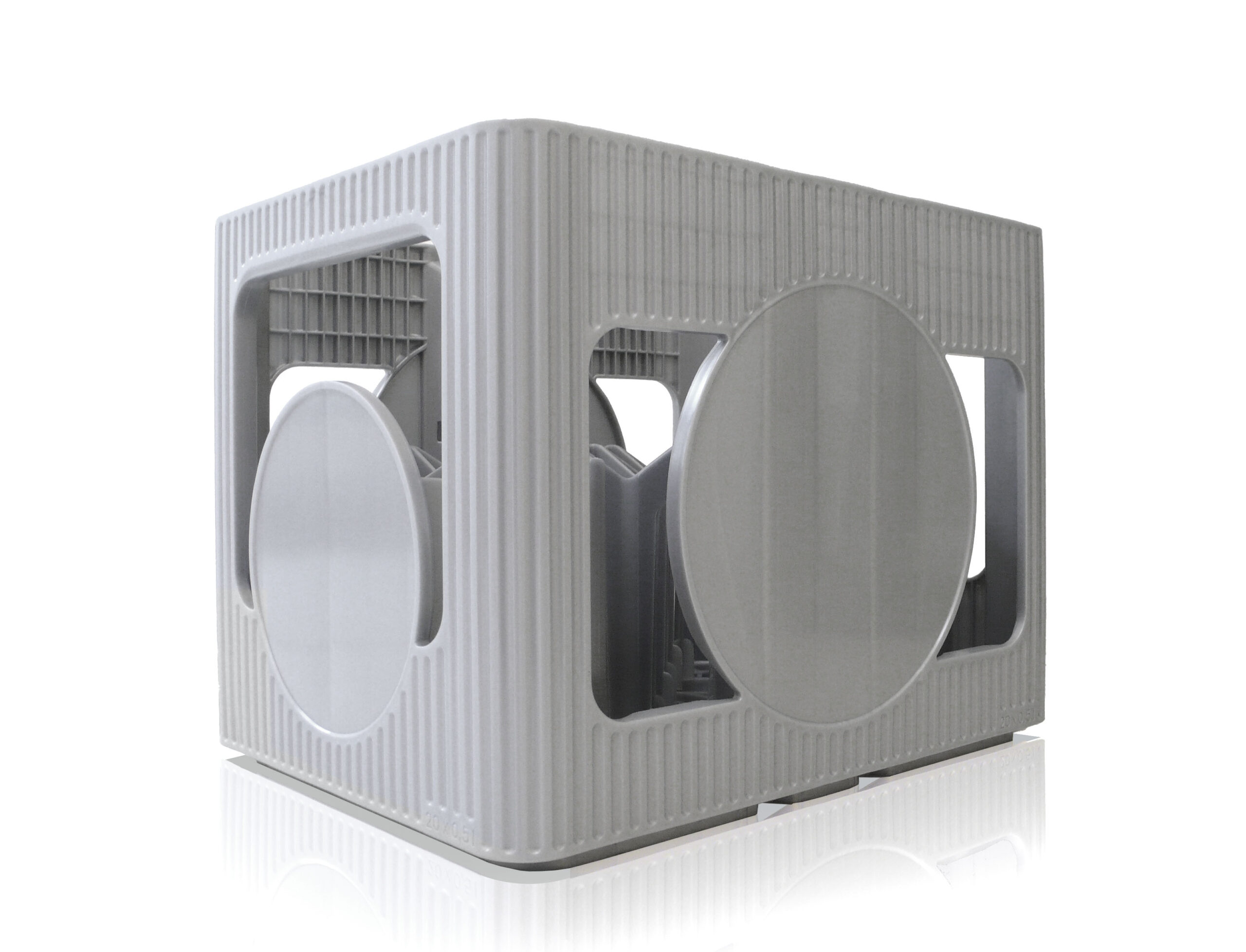

Another advantage: as we envisioned circular brand vignettes for the new system, the brands were required to concentrate their appearance as clearly and iconically as possible on a round disc: One circle for all, all for one circle.

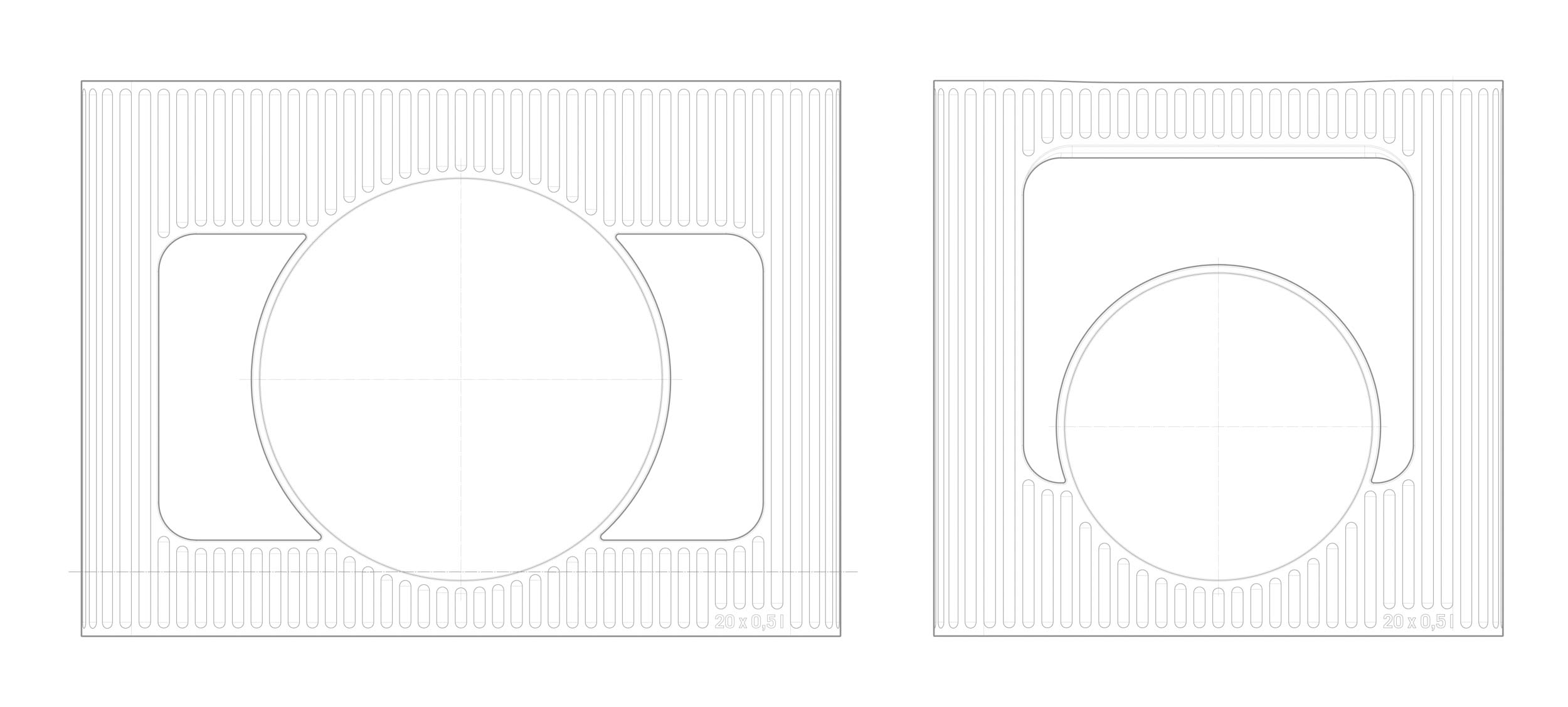

We designed the static structure of the crates with as little material as possible. Ribs, struts and beading made them light and durable. The textured surface with its contrast of light and dark reduces visible signs of use so that it retains its value even after many years of use. To remove the labels in the cleaning plant, we shaped the circular surface to easily remove them with a jet of water.

The proof of concept test set-up in the brewery halls.

A circular win-win.

The basic crate range has been implemented over 15 years ago and is still a successful system which is updated constantly. The possibility of relabeling has significantly reduced the number of crates in circulation. Manufacturing the crates from just one material is more cost-effective and increases their recyclability at the end of the product cycle. The basic crate system proves that the circular way of thinking conserves resources and enables companies to effectively combine standardization and individuality. A true circular win-win.